The semi -

Automatic Powder Coating Line, with a starting cost of approximately $20,000, serves as an ideal solution for mid - sized manufacturers. While it incorporates an automated conveyor system, the powder application process still necessitates a degree of manual involvement. This blend of automation and human touch allows for a balance between cost - effectiveness and production flexibility.

On the other hand, the fully

Automatic Powder Coating Line, commencing at $50,000, is meticulously engineered for large - scale production facilities. It offers end - to - end automation, seamlessly handling every stage from powder - feeding to curing, all under the purview of intelligent control systems. This high - tech setup ensures maximum productivity and consistent quality, making it a top choice for high - volume operations.

Both types of

Automatic Powder Coating Lines operate on the principle of electrostatics. As the workpiece glides along the conveyor, the powder is electrostatically charged and then evenly distributed onto its surface. This method is designed to enable high - speed, high - quality production, meeting the rigorous demands of various industries. Additionally, most suppliers offer comprehensive services, including installation, operator training, and ongoing maintenance, to ensure smooth operation of the equipment.

In the automotive sector, fully

Automatic Powder Coating Lines are the go - to choice for mass - coating car bodies, where precision and speed are of utmost importance. In appliance manufacturing, semi - automatic lines prove to be a practical option for coating metal parts, offering a cost - efficient way to achieve quality finishes. In the construction industry, these lines are deployed to coat large - scale metal components for buildings, ensuring durability and aesthetic appeal.

Q: How can I initiate the operation of the Automatic Powder Coating Line?

A: First and foremost, verify that all components are correctly connected and have a stable power supply. Subsequently, adhere to the startup procedures detailed in the user manual to activate the conveyor, powder - feeding, and spraying systems.

Q: What steps should I take if the powder coating thickness varies?

A: Thoroughly inspect the powder - feeding mechanism, conveyor speed, and electrostatic settings. Fine - tune these parameters to guarantee a uniform powder application and consistent coating thickness.

Q: Is it possible to customize the production speed of the automatic line?

A: Indeed, the majority of these lines are equipped with adjustable conveyor speeds. You can easily set the speed according to your specific production requirements, allowing for optimal production efficiency.

Q: How frequently should I perform maintenance on the Automatic Powder Coating Line?

A: It is recommended to conduct regular maintenance on a monthly basis. During this time, check for signs of wear and tear in moving parts and ensure that both the powder - feeding and curing systems are in optimal working condition.

Q: How do I determine the most suitable automatic powder coating line for my needs?

A: Take into account your production volume, budget constraints, and the desired level of automation. For high - volume production scenarios, a fully automatic line is the more fitting option. For mid - scale production, a semi - automatic line can offer an excellent balance between cost and functionality, making it a cost - effective choice.

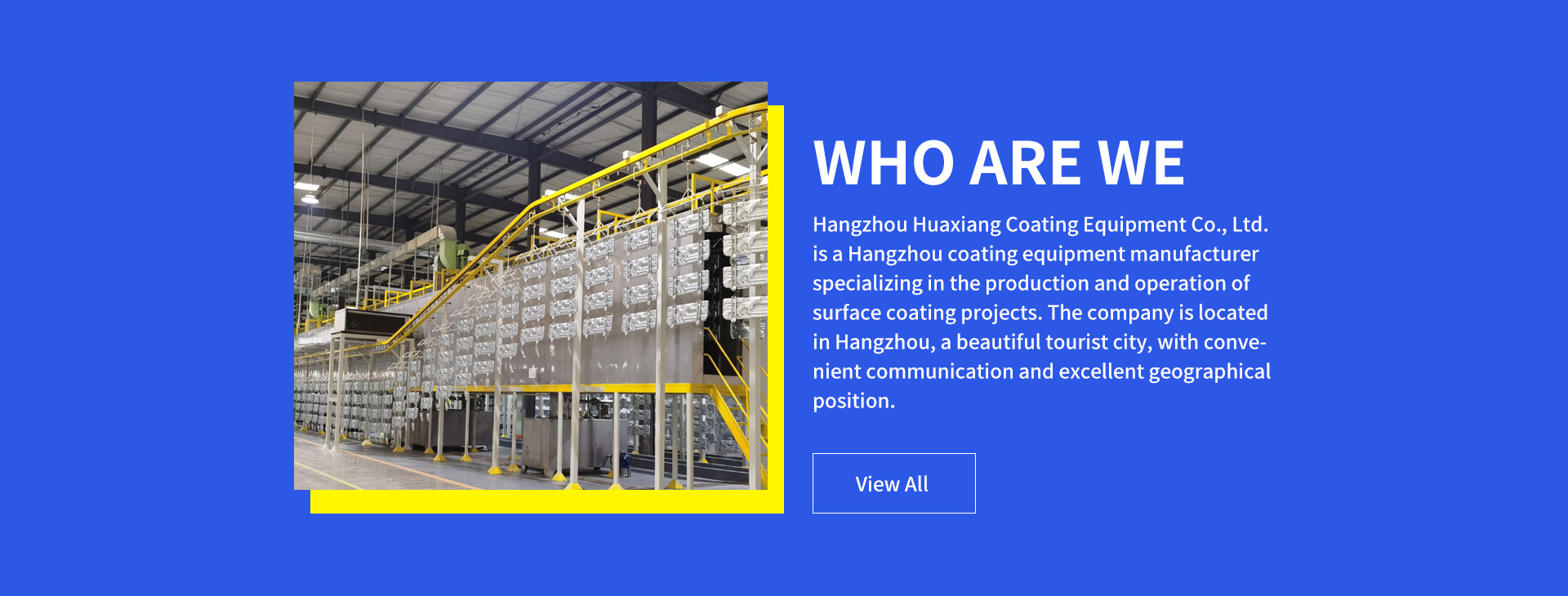

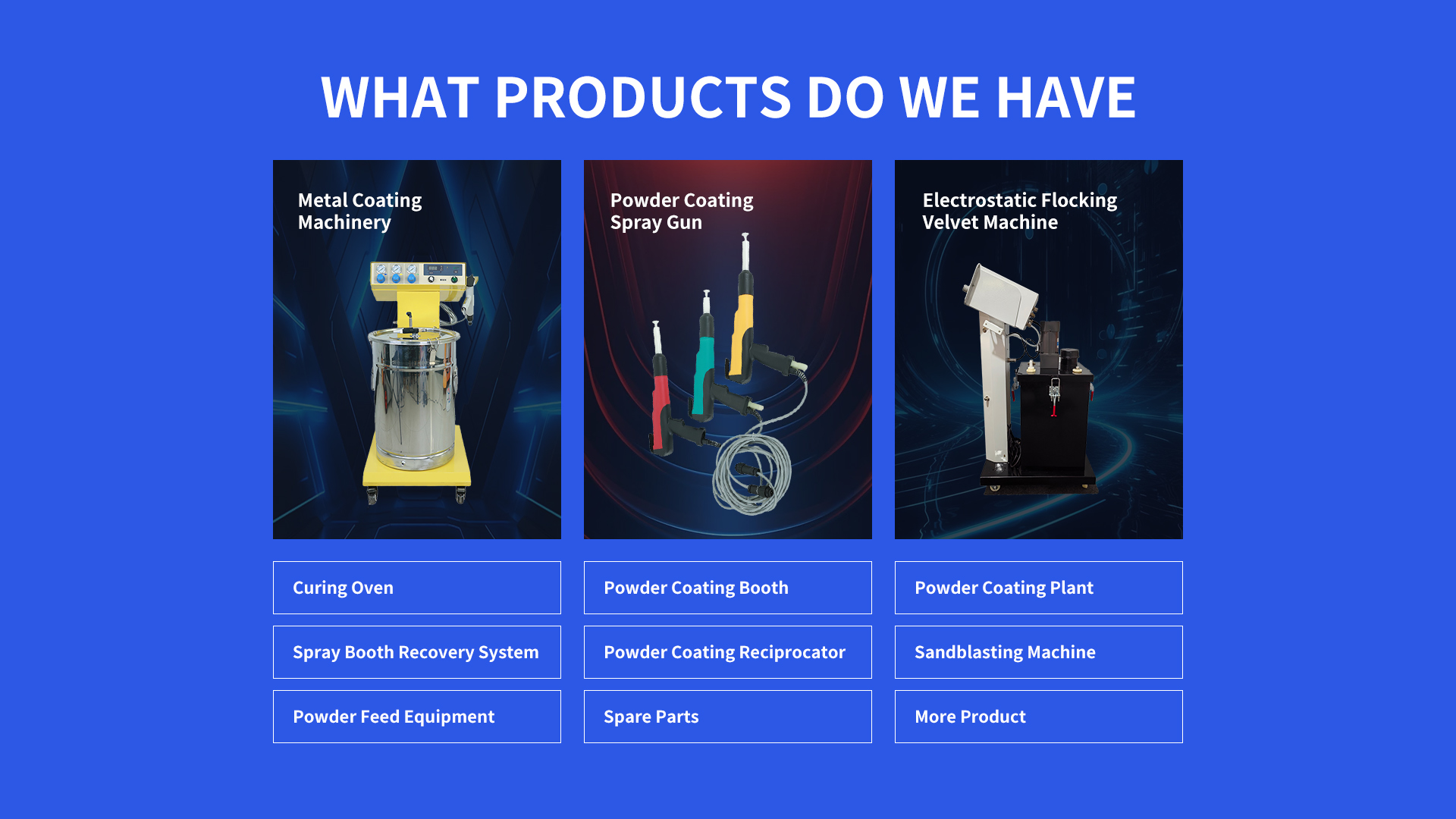

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com